Concept Development | Prototyping | Mechanical Design | CAD

From Idea to Functional Prototype

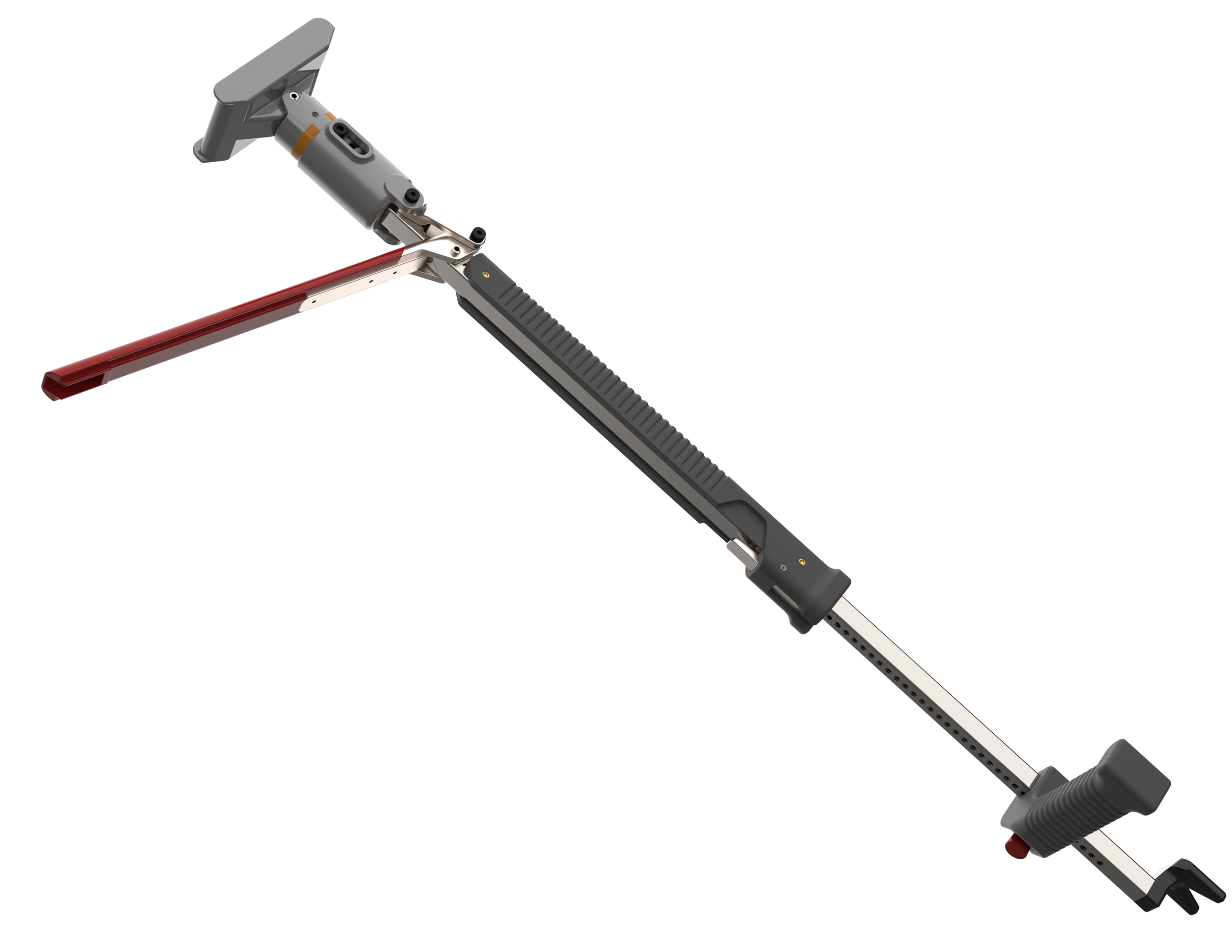

Inventor Johnathan Roberts wanted help making his idea into something he could use and test, so we created a functional prototype to demonstrate and test his invention.

What We Did

Proof-of-Concept Prototype

At the start of the project, the client knew what problem he was trying to solve and had a rough idea for a device that could help people get in and out of a vehicle, but wasn't sure how to get it to work. We started this project by building a simple functional prototype that was able to quickly embody his idea into something he could use and test. With something tangible that worked, we started to think about how it could be made into a real product and refine the prototype design into something he could show others and do real-world testing.

Ideation Sketches

We generated a lot of ideas for different features and mechanisms to explore how the device could work. We considered the structure and mechanics as well as the user interaction and touchpoints. We also started thinking about form, materials and fabrication possibilities.

Bread Board Prototypes

In parallel to the sketch ideation, we started building prototypes that were modular and easy to modify. We used these prototypes to test our assumptions and ideas and discovered things we had not considered. We explored variations on different mechanisms and user touchpoints as well as different materials and geometries. We then were able to combine the best features into a single concept.

CAD Modeling

Unlike the bread-board prototypes which were mostly hacked together from off-the-shelf parts, the final concept we created needed to be entirely custom. We used CAD modeling and simulations to design the assembly and ensure that the parts would be strong enough for a reliable, functional prototype. At this stage we also started considering how this could be turned into a production product.

Functional Concept Prototype

Using a combination of advanced additive manufacturing technologies and traditional metal shop skills, we created a physical, functional prototype of the product concept that the client was able to use to test with potential users and demonstrate to potential investors.

How can we help with your project?

Devise Designs, LLC

3330 COBB PKWY NW STE 324 -366,

ACWORTH, GA 30101

1-(678)-310-4798

Would you like to share your cookies with us?

We use cookies to analyze website traffic. By sharing your cookies with us, we can better understand our web presence. Would you like to share some cookies?